Before the year 2015 comes to an end, I would like to share the weaving project I did a couple of weeks ago.

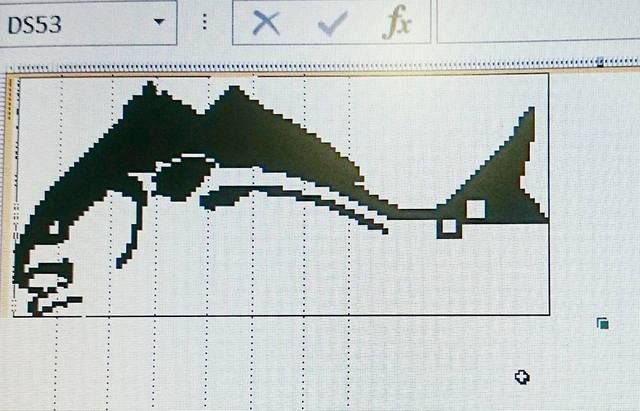

I borrowed this image from Joe Vargo which he posted in his facebook and it was very nice. I improvised the tail slightly when I plotted it out in excel format.

Yes, in excel format not the weaving software.

Here is how is look like.

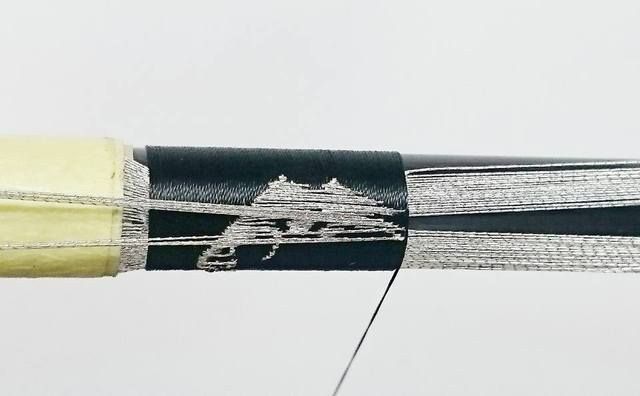

Bit by bit and square by square.

I made myself a weaving jig by using cardboard and in no time I kicked off this weaving project of mine.

Half way through....

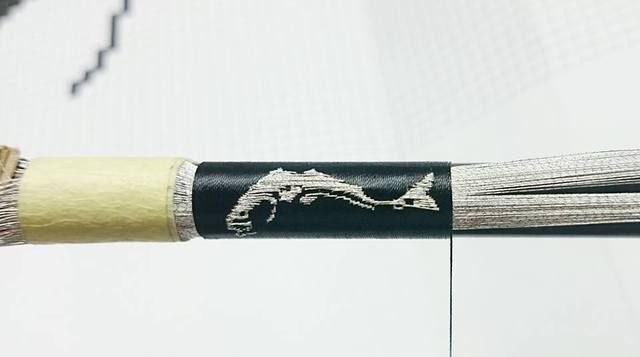

Almost done. I just need to finish off the thread and pack it nicely.

There at last. Next it will neeed several coat of epoxy. But it got to wait awhile.

I will show the finished coated weaving when I complete this light spinning rod project soon...

Thursday, December 31, 2015

Monday, November 30, 2015

Solid GLASS Prawning ROD

I have used factory made 2 section prawning rod and most often the time, it would not last for two or three sessions before something happened it. I knew I had to built one for the prawn....

I got myself a couple the solid glass blanks from MATAGI and start a new project... "The ROSENBERGII project"

The original action of the glass blank was quite stiff for prawning. I had to trim down the OD of the blank to make it softer especially at the tip section. The best thing of working with solid glass blank is that you can alter the bending and action to your own liking.

I used SG Graphite reel seat with quick lock and matt carbon tube insert for

the handle.

Guides inline

Finishing at the reel seat beneath the quick lock hood with Fuji winding check

Well, this rod will be put to test on the next prawning session.

UPDATED 11 JANUARY 2016

Just last weekend I tested this rod for prawning at Kinta River. The catch rate was not very good but I managed to hailed up a few good size.

This rod is soft and able to see it tapping when the prawn took the bait, but it is still not sensitive enough.

I think I have to make another rod with smaller taper for a change. Making it as sensitive as possible at the tip while maintaining a good backbone at the rear.

I got myself a couple the solid glass blanks from MATAGI and start a new project... "The ROSENBERGII project"

The original action of the glass blank was quite stiff for prawning. I had to trim down the OD of the blank to make it softer especially at the tip section. The best thing of working with solid glass blank is that you can alter the bending and action to your own liking.

I used SG Graphite reel seat with quick lock and matt carbon tube insert for

the handle.

EVA fighting butt

Guide setting

Rod action

SG- SiC K-guide after epoxy

Guides inline

Completed handle

Finishing at the reel seat beneath the quick lock hood with Fuji winding check

Well, this rod will be put to test on the next prawning session.

UPDATED 11 JANUARY 2016

Just last weekend I tested this rod for prawning at Kinta River. The catch rate was not very good but I managed to hailed up a few good size.

This rod is soft and able to see it tapping when the prawn took the bait, but it is still not sensitive enough.

I think I have to make another rod with smaller taper for a change. Making it as sensitive as possible at the tip while maintaining a good backbone at the rear.

Thursday, November 26, 2015

Testing the WHITE glass

Finally I had my change to test it out..

Effortless cast with the 3WF line out around 30 feet and it's action was as usual... CRISPY!

A final touch before I pack it up in the rod sock.

Effortless cast with the 3WF line out around 30 feet and it's action was as usual... CRISPY!

A final touch before I pack it up in the rod sock.

Labels:

2/3wt,

fiberglass blanks,

Translucent fly rod,

UL,

white

Tuesday, October 27, 2015

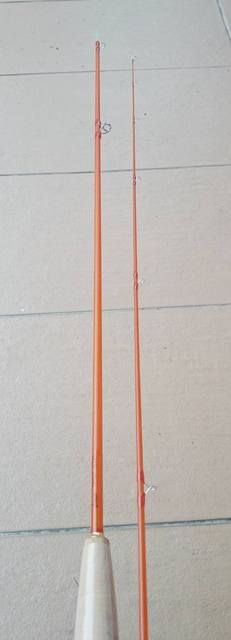

CLEAR WHITE fiberglass UL fly rod

Completed this UL fiberglass fly rod 2 weeks back but have yet to test it..

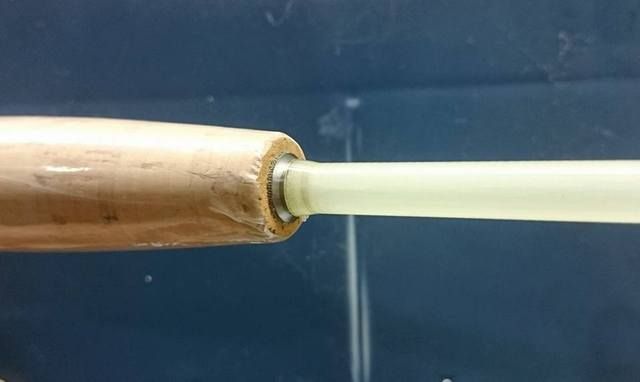

Uplocking burled wood insert with engraved band and locking nut.

Translucent clear white fiberglass fly rod blank with winding check at the cork grip.

Can't see much of the fly rod against the white color background.

Hope I would get a chance to test it in the garden over this coming weekend.

Uplocking burled wood insert with engraved band and locking nut.

Translucent clear white fiberglass fly rod blank with winding check at the cork grip.

Can't see much of the fly rod against the white color background.

Hope I would get a chance to test it in the garden over this coming weekend.

Thursday, October 15, 2015

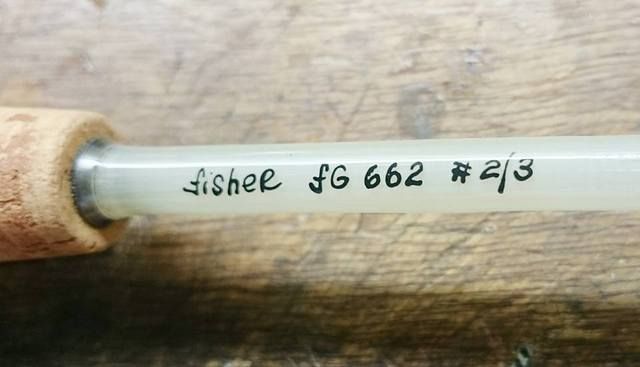

Fiberglass AmbeR 6'6" 2/3wt Fly Rod

This is the last piece of such blank in my keeping. I want to finish this fly rod with the standard simplest way a fly rod should be. No fancy inlays and no fancy wrapping.

Amber is the color of this fiberglass blank. It is neither orange nor yellow. Not brown either.

The handle setup was done many months ago. This project was put on hold for my jigging rod built.

Half wells cork grip with timber insert up locking reel seat.

I prefer to use nylon threads on fly rods. I just love the effect of the threads when it is coated with epoxy.

After the wrapping was epoxy.

No decals but just hand sketch of the rod info on the rod

And to finish off this rod, the cork handle are sealed with cork seal.

and done..

Amber is the color of this fiberglass blank. It is neither orange nor yellow. Not brown either.

The handle setup was done many months ago. This project was put on hold for my jigging rod built.

Half wells cork grip with timber insert up locking reel seat.

I prefer to use nylon threads on fly rods. I just love the effect of the threads when it is coated with epoxy.

After the wrapping was epoxy.

No decals but just hand sketch of the rod info on the rod

And to finish off this rod, the cork handle are sealed with cork seal.

and done..

Friday, October 2, 2015

Maroon '5' from Langkawi

The 'maroon' blank travels 420 km to reach me.. Yes, 420 km from Langkawi island to Puchong.

Not sure of the origin of this blank, but it's a 4 section graphite blank with fast action and rated at 5wt according to the owner of the blank.

Handle set up for this fly rod. Full wells cork grip, down locking reel seat with burl wood insert and the EVA bottom fighting butt.

Nylon 'scarlet' thread for the wrapping.

Wrapping of the stripping guide before epoxy.

This is how it look after epoxy. I must say the 'scarlet' thread really goes well with this blank.

Completed the guide wrapping pending epoxy.

Done with the epoxy

And finally, seal up the cork handle

Not sure of the origin of this blank, but it's a 4 section graphite blank with fast action and rated at 5wt according to the owner of the blank.

Handle set up for this fly rod. Full wells cork grip, down locking reel seat with burl wood insert and the EVA bottom fighting butt.

Standard snake guides

Nylon 'scarlet' thread for the wrapping.

Wrapping of the stripping guide before epoxy.

This is how it look after epoxy. I must say the 'scarlet' thread really goes well with this blank.

Completed the guide wrapping pending epoxy.

Done with the epoxy

And finally, seal up the cork handle

Friday, September 25, 2015

Rod up-keeping and maintenance

There are so many skilled fisherman out there, may it be fly fishing, bait casting, bait jigging, popping, bottom fishing and the list goes on, they took good care of their reels but not many of them really thought of rod maintenance.

Similarly to reel maintenance, rod maintenance to will extend the life span of the rods. It is much more simpler than servicing the reel.

Proper cleaning of reel seat, the handle and the guides. The only thing which is kinda difficult to do is getting rid of the rust built up at the guide foot and cracks at the wrappings.

Rust will eventually build up at guide foot when come in contact with salt water.

A small gap, cracks or void area between the epoxy coating and the guide foot is good enough for the water to penetrate and sip in.

Of course it will not rust over night, but this will be the beginning of the corrosion process especially to salt water rods.

The corrosion or rust build up normally starts on the surface of the guide foot just beneath the epoxy coating, and it will get deeper if the rust particles are not scrap off.

The surface of the old epoxy coating was lightly scuffed to remove the dirt.

The new thin epoxy coating is then applied onto the scuffed wrapping.

And as you can see, the rusty particles are scrapped off the guide foot.

If the epoxy are properly and evenly applied onto the wrapping sealing off all the gaps and voids, the guide foot will be rust free for at least a couple of years.

I hope this write-up will give you a new perspective about up keeping your rods and additional information to extend the lifespan of your fishing rod.

Similarly to reel maintenance, rod maintenance to will extend the life span of the rods. It is much more simpler than servicing the reel.

Proper cleaning of reel seat, the handle and the guides. The only thing which is kinda difficult to do is getting rid of the rust built up at the guide foot and cracks at the wrappings.

Rust will eventually build up at guide foot when come in contact with salt water.

A small gap, cracks or void area between the epoxy coating and the guide foot is good enough for the water to penetrate and sip in.

Of course it will not rust over night, but this will be the beginning of the corrosion process especially to salt water rods.

The corrosion or rust build up normally starts on the surface of the guide foot just beneath the epoxy coating, and it will get deeper if the rust particles are not scrap off.

The surface of the old epoxy coating was lightly scuffed to remove the dirt.

The new thin epoxy coating is then applied onto the scuffed wrapping.

And as you can see, the rusty particles are scrapped off the guide foot.

If the epoxy are properly and evenly applied onto the wrapping sealing off all the gaps and voids, the guide foot will be rust free for at least a couple of years.

I hope this write-up will give you a new perspective about up keeping your rods and additional information to extend the lifespan of your fishing rod.

Wednesday, September 23, 2015

Another #EPIC story and more to come...

This another EPIC job I picked up earlier and completing it before my 4 days break to the highlands.

It' a 3 section EPIC glass, 7'6" 3wt.

A very simple built with straight cork grip and standard guides.

Stacked cork rings for the grip.

Standard snake guides and stripping guide.

The first cork grip didn't really turn out nice and I had to do another. If I cannot accept the quality of the shaping, I don't think my friend would accept it either.

The sliding band reel seat and cork grip being put together.

Wrapping of stripping guide with brown nylon thread. My friend wanted the wrappings black and I told him , no worries. It will turn black... well almost black when I am done with it.

The wrapping after epoxy.

The completed rod.

Subscribe to:

Posts (Atom)