I dug into the world wide web and I found a very interesting forum where all of the forumers uses fiberglass fly rods. http://fiberglassflyrodders.yuku.com/

There are so much information on fiberglass fly rods that I got from this forum and the forumers taught me a lot of things especially in rod building. Looking at those glass rods built by pro builders such as Mark (Gypsy), Mike Mcfarland, Don ( Zenkoanhead) ... just to name a few, pushed me a step further in rod building. Their meticulous work never failed to amaze me.

That was the beginning of my second phase in rod building. I started off with affordable fiberglass blanks that I could find.... LAMIGLAS. Nice glass rod for that price range.

I bought a couple of Lamiglas blank, a few Mcfarland blanks and ordered some components from Anglers' Workshop and Mudhole. There is no looking back since ...

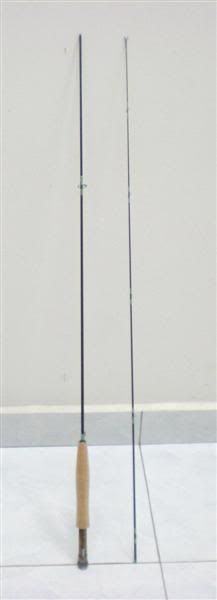

The first Lami I built, a 7' 2 pc 3wt

The 2nd Lamiglass, a 7'6" 2 pc 4wt

McFarland Spruce Creek 7'6" 3 pc 5wt

Mcfarland 6'5" 2 pc 3wt

The last of my Lami blank, another 7' 2pc 3wt with rattan grip

Diamond glass 7' 3pc 3 wt

The best part about rod building is the satisfaction of being able to complete the built and customizing the fly rod. I am a hobbyist rod builder and I enjoyed every moment and the process of rod building.

What's next?

I have thought of rolling my own fiberglass blank but there are too much stuff involved and I am not able to source for the raw materials let alone the space for me to do so.

My next best option is making bamboo fly rod blanks. There are ample of natural resource here and bamboo is easily available.

The rest is history.......................